EVA (Ethylene Vinyl Acetate) exhibits inherent mold resistance properties, including resistance to moisture absorption and microbial growth. When manufactured and maintained properly, EVA products, including those made by Bonito, can be mold resistant. Bonito, a trusted manufacturer, ensures the use of high-quality EVA materials and follows stringent production processes to enhance mold resistance.

Table of Contents

Introduction to EVA Material

Overview of EVA (Ethylene Vinyl Acetate)

Ethylene Vinyl Acetate (EVA) is a copolymer made from ethylene and vinyl acetate monomers.

Properties and Characteristics of EVA

EVA is highly appreciated for its unique blend of properties. It has excellent low-temperature toughness and resistance to UV radiation and stress-cracking. EVA’s versatility makes it suitable for various modification and compounding processes to cater to specific application requirements. Some of its physical characteristics include good clarity, gloss, and low-temperature toughness. It also possesses good resistance properties against chemicals, UV radiation, and stress-cracking. These attributes make EVA a suitable material for various applications across industries.

Importance of Mold Resistance in Materials

Materials like EVA are often exposed to environments conducive to mold growth, which can degrade the material’s physical properties and aesthetic qualities. EVA exhibits good mold resistance, an attribute that is critical in applications that demand longevity and durability. The mold resistance of a material not only impacts its life cycle but also its performance in various applications, particularly those that expose the material to humid or damp conditions. In the case of EVA, its mold resistance enhances its applicability in diverse sectors like footwear, sports equipment, packaging, and more.

Mold Resistance of EVA Material

Inherent Properties of EVA for Mold Resistance

EVA, as a synthetic material, possesses inherent mold-resistant properties. This is largely due to its closed-cell structure which provides no organic material for mold spores to feed on.

Factors Affecting Mold Resistance in EVA

Although EVA has natural resistance to mold, certain factors can affect its mold-resistant properties. For instance, the thickness of EVA material can impact its resistance to moisture absorption and subsequently, mold growth. Thicker sheets may provide more resistance to moisture intrusion. Similarly, the overall quality and composition of the EVA can play a role. High-quality EVA with fewer fillers and additives often exhibits superior mold resistance. Additionally, the environmental conditions, such as humidity levels and exposure to water, can also impact the mold resistance of EVA material.

Comparison with Other Materials

Compared to other common materials like wood, cotton, and certain types of plastics, EVA offers superior mold resistance. Wood and cotton, being organic, provide an ideal breeding ground for mold spores. Similarly, certain plastics, although synthetic, can allow mold growth if they absorb moisture or have organic additives. EVA, on the other hand, due to its synthetic nature, resistance to moisture absorption, and absence of organic content, exhibits excellent mold resistance, making it a preferred choice for many applications.

Benefits of Mold-Resistant EVA

Durability and Longevity

This advantage is mainly due to EVA’s resistance to microbial attacks, which slows the degradation process and extends the material’s lifespan. For instance, EVA-based products like shoe soles or mats can serve reliably for several years without signs of mold damage, making them a cost-effective choice in the long run.

Hygiene and Health Considerations

Mold-resistant EVA also offers significant benefits when it comes to hygiene and health. Using mold-resistant EVA can prevent these health risks by inhibiting mold growth, ensuring the products remain clean and safe to use.

Applications in Moisture-Prone Environments

The mold resistance of EVA lends itself to a variety of applications in moisture-prone environments. One such application is in outdoor gear, including camping mats, tents, and water-resistant cases.

Another important application is in the construction industry, particularly in the manufacturing of waterproofing membranes. These membranes, often placed under the concrete slabs or behind the shower walls, face constant moisture exposure, and using mold-resistant EVA ensures these membranes last longer without any mold damage.

Lastly, EVA is extensively used in aquatic sports equipment like surfboards or swimming floatation devices. These items are frequently in contact with water and humidity, so using mold-resistant EVA helps prolong their lifespan and maintain their performance.

Case Studies: Mold Resistance in EVA Applications

Examples of Successful Mold Prevention in EVA

A significant instance of successful mold prevention in EVA comes from the toy industry. LEGO, a renowned toy manufacturing company, uses EVA for many of its products, particularly those designed for use in water. The company’s commitment to safety and hygiene led to the choice of EVA for its mold resistance, ensuring the toys stay mold-free even with prolonged exposure to moisture. This characteristic is crucial in a hospital setting where hygiene is a top priority. Mold-resistant EVA mattresses provide a safer and cleaner environment for patients, reducing the risk of mold-related health issues.

Real-life Scenarios and Solutions

One real-life scenario involving the use of mold-resistant EVA involves outdoor gear such as camping mats and tents. In one instance, an outdoor gear manufacturer was facing complaints about mold growth in their camping mats. They switched to using mold-resistant EVA and saw a significant reduction in these complaints. The mold-resistant EVA mats were able to withstand the damp camping conditions without allowing mold growth, improving customer satisfaction and the product’s overall lifespan.

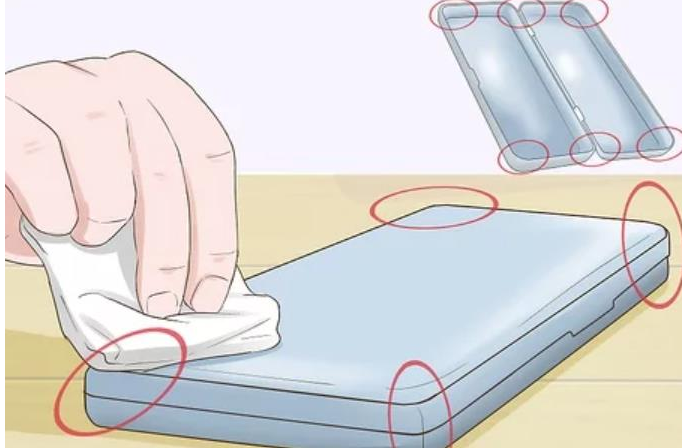

In another scenario, a company producing waterproof cases for electronics was experiencing issues with mold growth within the cases during shipping, due to the high moisture levels in the cargo holds. The company decided to switch to mold-resistant EVA for the case interiors, effectively solving the problem. These real-life scenarios illustrate the practical benefits of using mold-resistant EVA in applications susceptible to moisture exposure and potential mold growth.